In recently years, there are many people have known the difference between chemical fertilizer and organic fertilizer. So most of people choose organic fertilizer as their fertilizer. With this phenomenon, a lot of fertilizer granulation plants have appeared. It’s no doubt that start an organic fertilizer plant will make huge profits. Do you also want to be an organic fertilizer manufacturer and earn more money? If the answer is “yes”, then you come to the right place.

What is organic fertilizer made of?

If you want to start a fertilizer granulation plant for making organic fertilizer, the first thing you should know is the raw material. You have to know the raw materials for fertilizer industry.

To be honest, there are many materials can be used to make organic fertilizer. For example, livestock manure (pig dung/cow dung/chicken manure/sheep manure/vermicompost), sludge and garbage, filter mud from sugar mill, worse slag cake and straw sawdust, etc. Before using these materials, you have to distinguish clearly. Do not mix glass slag, plastic and other non-organic materials into your organic fertilizer manufacturing process. Because these material will harm your crops. If you just want to make a simple composting system for your own garden. You can collect egg shell, vegetable waste and other living garbage to make a compost bin.

Organic fertilizer pelleting equipment for sale

- Model: SEECJZ-600 (can be customized)

- Installation angel: 2°-2.5°

- Capacity(t/h): 1-1.5

- Total power(kw): 37

- Moisture of feeding material: 20%-40%

- Dimensions: 4100×1600×1150

How to make granular fertilizer?

As we all know, the organic fertilizer has many benefits. But as an organic fertilizer manufacturer how can we make high-quality organic fertilizer? If you start a fertilizer granulation plant, you should know the organic fertilizer granulation process. To be honest, the organic fertilizer manufacturing process is not easy. We have to use special machines to make it. Then we will introduce the organic fertilizer manufacturing process.

High yield manure pellet mill for sale

- Model: SEECZJZ-1060

- Production capacity: 5-8 t/h

- Shape size: 7250×1250×1670

- Installation angel: 2°-2.5°

- Total power: 7.5+18.5kw

Ten steps to make organic granular fertilizer

There are the steps to make pellet fertilizer for your organic fertilizer granulation plant.

The first step you should use solid-liquid separator machine to dehydrate the material. If the material is too wet, it cannot enter the next crushing step.

The second step is crushing link. Before enter to the next step we should use new type vertical crusher to make the raw material smash.

Then we can go to the next step-fermentation. That is the important step for making pellet fertilizer. SEEC groove type compost turner will accelerate material fermentation. If you adopt the traditional fermentation method will take you almost 60-70days. But if you use our groove type compost turner to ferment your raw material will only take 15-20days.

Because some materials may not have been crushed, so we have to crush these unqualified material again.

Mixing organic fertilizer powder with a disc mixer.

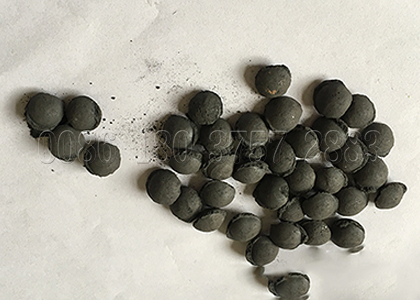

Next is the most important part of the organic fertilizer production process-granulation. If you want to get the organic granular fertilizer, you have to use granulation equipment. Through our organic fertilizer pellet machine, you will get perfect organic granular fertilizer.

Organic fertilizer pellet making machine for your fertilizer granulation

- Model: SEECJZ-600 (can be customized)

- Installation angel: 2°-2.5°

- Capacity(t/h): 1-1.5

- Total power(kw): 37

- Moisture of feeding material: 20%-40%

- Dimensions: 4100×1600×1150

In order to reduce the moisture of granular fertilizer, we should use rotary drum drying machine to achieve this goal.

Cooling. Rotary drum cooling machine is to cool your pellet fertilizer and easy to store.

Screening. For purpose of get quality pellet organic fertilizer, we can use rotary screen machine to screen out the unqualified particles.

Coating. We should pack the granule fertilizer with a rotary coating machine.

Organic fertilizer pellet machine for sale

- Model: SEECZJZ-1060

- Production capacity: 5-8 t/h

- Shape size: 7250×1250×1670

- Installation angel: 2°-2.5°

- Total power: 7.5+18.5kw

Disc granulator

Disc pellet making machine adopts the whole circular arc structure, and the granulating rate can reach more than 93%. It has three discharging parts, which are convenient for discontinuous production, greatly reducing the labor intensity and improving the labor efficiency. The reducer and motor adopt flexible belt drive to start smoothly, slow down the impact force and improve the service life of the equipment. The plate bottom strengthen by a plurality of radiant steel plates, which is durable and never deformed. It is an ideal equipment for organic fertilizer plant and compound fertilizer production line, which is designed with thick, heavy and strong base. So it has no fixed anchor bolts and smooth operation.

Disc granulator for your fertilizer factory

- Model: SEECYZ-1500(can be customized)

- Edge height(mm): 300

- Rotary speed(r/min): 21

- Motor power(kw): 3

- Capacity(t/h): 0.5-0.8

- Dimensions: 1760×1500×1950

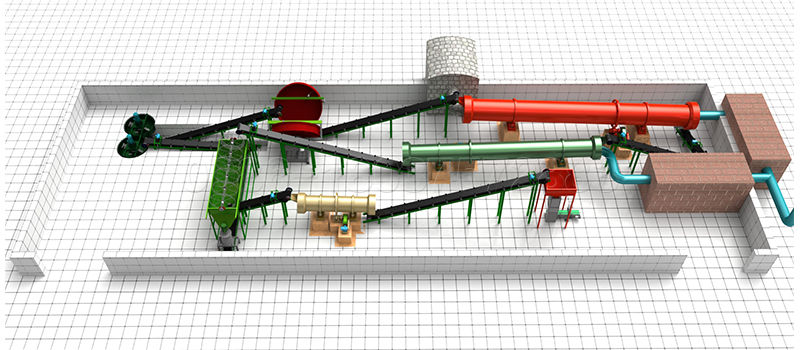

Complete fertilizer granulation plant for sale.

If you want to start a fertilizer granulation business, it’s necessary have a fertilizer granulation plant. Whether you want to start an organic fertilizer granulation plant or compound fertilizer granulation business, having a fertilizer granulation plant will reduce you a lot of time and money. There is a complete fertilizer plant for sale. In SEEC, we have organic fertilizer production line, compound fertilizer production line, pellet production line and powder production line. Thus, whatever kind of production line you want, SEEC can provide it for you. In addition, SEEC fertilizer machinery can provide profession installer to help you. Our installer can go to your country to help you install the production line. You see, we not only provide high quality production line, but also provide good after-sales service.

Double roller extrusion granulator in fertilizer granulation plant

- Model: SEECWJ-1T(can be customized)

- Power(kw): Granule diameter≤4.5m: 11

- Granule diameter>4.5m: 15

- Granule diameter(mm): 3-10

- Roller sheet size(mm): 150×220

- Dimensions(mm): 1450×800×1450

Application of organic fertilizer

Organic fertilizer as a nutrient-rich fertilizer, it has an extensive application. So what is fertilizer used for? This is the important question you have to know. Generally speaking, there are many places we can use organic fertilizer. Whether it’s a large farm or a backyard garden, we can use organic fertilizer. Using organic fertilizer can increase grain yield. And organic fertilizer not only can be used in farm land, but also can as a fertilizer apply to the urban green space. It can make the grass and trees greener and more beautiful.

The beneficial effect of organic fertilizer on farmland

In addition, organic fertilizer can also as a soil conditioner apply to the farm land. Due to apply chemical fertilizer to the farm land for a long time. Which will cause dispersion of soil particles, thus damaging the soil aggregate structure, resulting in serious soil consolidation and ultimately losing the value of agricultural cultivation. Organic fertilizer can change this situation and make farmland fertile again. Because of this serious land problem, the application of organic fertilizer becomes more and more necessary.

How to choose a suitable organic fertilizer granulation machine?

The importance of choosing a suitable organic fertilizer granulation machine is that you have to know what kind of fertilizer pellets that you want to produce. Maybe some people want to make flat ball shape fertilizer pellets. So you have to choose different fertilizer granulation equipment to meet your requirements. Furthermore, you also should choose a good organic fertilizer granulation machine manufacturer. A good fertilizer manufacturer will provide many professional suggestions. For example, the fertilizer granulation equipment maintenance is also important. If you can maintain the granulator well, it will prolong the service lifetime of your fertilizer pellet mill. And if you want to build a small fertilizer granulation plant, you can choose our small scale fertilizer granulator-pan granulator to meet your needs.

Organic fertilizer granulator for your fertilizer granulation plant

- Model: SEECJZ-1200 (can be customized)

- Installation angel: 2°-2.5°

- Capacity(t/h): 4-6

- Total power(kw): 90

- Moisture of feeding material: 20%-40%

- Dimensions: 4900×2550×1800

Where can you find the fertilizer machine manufacturer?

Starting an organic fertilizer granulation plant should have good pellet fertilizer making machine. And you have to find the good fertilizer machine manufacturer.

- You can find the fertilizer manufacturer through your friend and relatives. Maybe they know the place where you want to find.

- You can also find fertilizer manufacturing plant online. There are a lot of information on the internet.

- SEEC as an organic granular fertilizer manufacturer with over 30 years production experience. We have various pellet making machines what you want.

SEEC fertilizer machinery has all kinds of fertilizer granulator machines. Next we will introduce one of them.Except that, we also have new type organic fertilizer granulation equipment, double roller extrusion granulator, new type double roller pellet making machine, rotary drum granulator and organic fertilizer polishing machine.