With the economy development, more and more people have realized the importance of environmental protection. Especially in the land, most person want to find an eco-friendly fertilizer for their crops. Thus, the organic fertilizer becoming popular. According to this situation, there are many fertilizer manufacturers want to start an organic fertilizer production plant to produce organic fertilizer. FPD has the most suitable organic fertilizer equipment, and our fertilizer plant for sale at your request.

What kind of fertilizer production line provided by ShunXin Fertilizer Plant Dsigner?

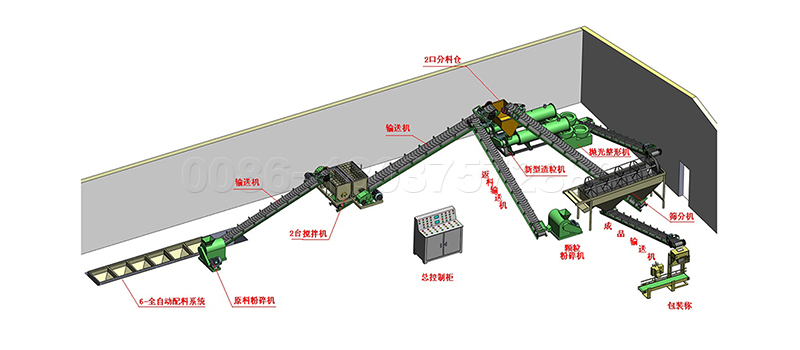

The whole organic fertilizer production line for sale

FPD organic fertilizer production line is one of the main organic fertilizer production lines. Here you can know the production process of organic fertilizer production line.

1. First you should prepare the raw material that you want to make organic fertilizer . Such as, livestock manure, sludge and garbage, filter mud from sugar mill, worse slag cake and straw sawdust and other organic waste . These raw material should not mix with the plastics, glass, metals etc. Then you can use chain plate type compost turner to make the material ferment.

2.Next, you should use our new type vertical crusher to crush the fermented material. You should notice that the organic material must meet the requirement of granulation.

3.Granulating. As the most important part of the organic fertilizer production line, you should take this process seriously. And the quality of the organic fertilizer pellet machine should be the best. Our fertilizer plant for sale rotary drum stirring granulator to make fertilizer pellets.

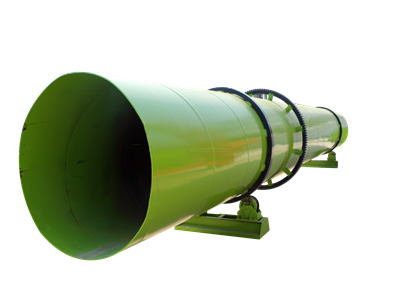

4.Drying. After granulating, the moisture content of organic fertilizer is too high to pack. You had better using a rotary drum dryer for lowering the pelleted organic fertilizers’ moisture content.

5.Cooling. In order to ensure the pellets quality, the particles should be cooled after drying with the help of rotary drum cooling machine. It’s necessary for the process of the organic fertilizer production line.

6.Screening. Maybe there are some unqualified granular fertilizer during the production. Therefore, the vibrating screen machine is needed.

7.Packaging. We all know that all the product we use is packaged, and the organic fertilizer pellets also should be packaged.

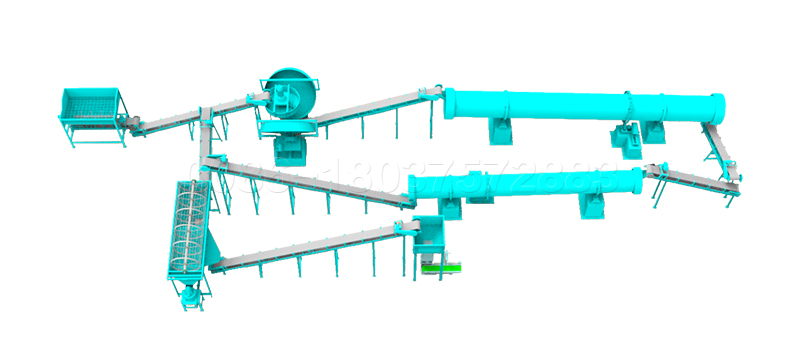

Fertilizer granulation production line for sale

The fertilizer granulation production is similar to the organic fertilizer production process. Here are the fertilizer granulation production line.

- In order to make granular fertilizer, you need to prepare the powdery fertilizer first.

- Then you can enter the process of granulating. As the important part of the production line, we should use the fertilizer granulator machine to granulation. After this process, we can get beautiful organic pellets.

- Rotary drum drying machine and rotary drum cooling machine will make organic pellets meet the requirements of packaging.

- The rotary screen machine will screen out unqualified pellets and qualified pellet for entering the next step.

- Packing. Packing machine is help to pack the organic fertilizer pellets. We have various packing machine. Such as single bucket automatic packing scale, double bucket automatic packing scale and no bucket automatic automatic packing scale. If you have a large scale fertilizer production line, you can choose the double bucket automatic packing scale.

That is the whole fertilizer granulation production line. If you want to build a fertilizer granulation plant, it’s useful for your project.

What should you know when choosing a site for a fertilizer plant?

Generally speaking, you should choose a good place to product organic fertilizer and compound fertilizer. Here are the requirements of building a fertilizer plant.

- Plants should be located close to the supply of raw materials and fuel. It should also choose areas with good conditions for cooperation in storage, transportation, machine repair, public works and living facilities.

- The factory site shall be close to the place with sufficient water, good water quality and sufficient power supply. With these conditions, the fertilizer production equipment can work very well.

- And the factory site should be selected in a convenient transportation place.

- Fertilizer plant selection should pay attention to saving land, do not occupy or occupy less arable land. Your fertilizer area and shape of the plant area shall meet the needs of reasonable layout of the process flow. In addition, there should be room for appropriate development.

- After the fertilizer factory is put into operation, it shall make a preliminary evaluation of the impact caused by the surrounding environment

Four hot sale fertilizer plant types for sale

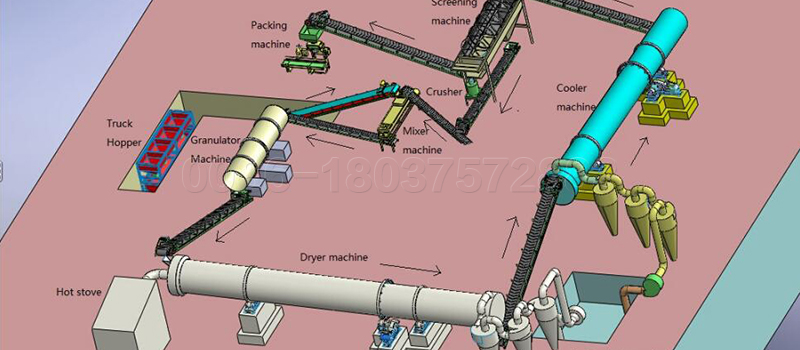

The granulation process of fertilizer granulation plant

- Mix qualified raw materials into a high efficiency mixer according to the matching requirements.

- Then taking the raw materials to the tray feeder to remove the iron content in the material during the conveying process.

- When the material enters the rotary drum churning granulator uniformly in the disc feeder, the material will be forced to pass between the two pressure rolls and extruded into a sheet. And the sheet is pressed by a coarse crusher under a pressure roller fragmented into pieces and then sieved, the material on the screen continues to be broken and screened.

- Next, transporting the semi-finished product to the finished product screening machine. The fine particles after the screening are directly returned to the tray feeder. The unqualified pellets are crushed by the cage crusher and returned to the disc feeder.

- After screening, the qualified products will delivere to the single bucket automatic packaging scale for weighing, packaging and store.

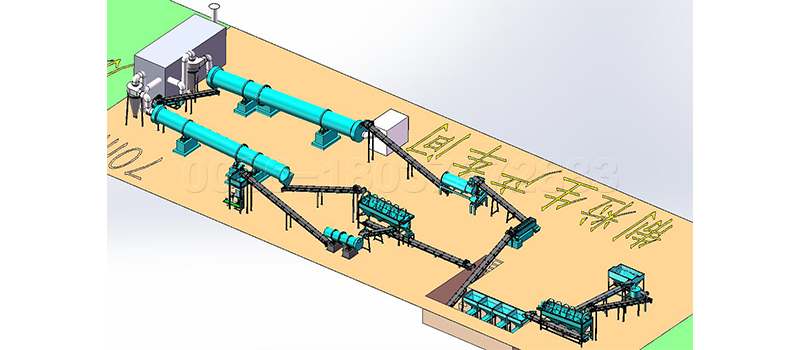

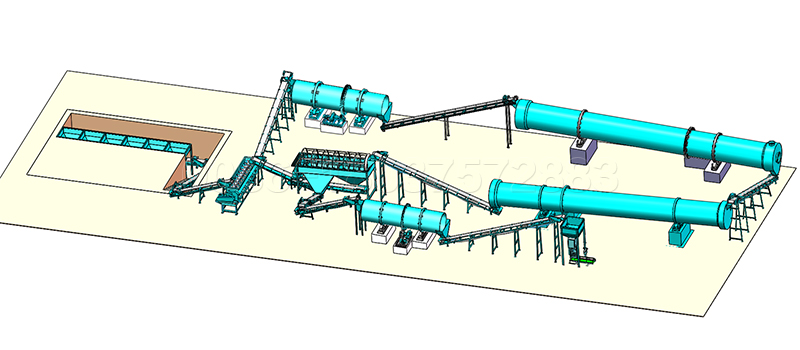

FPD compost fertilizer production line for your fertilizer plant

FPD organic fertilizer plant for sale

1.The first step you should use the solid-liquid separator machine to dehydrate the raw material. Before you use the raw material for making compost, you should go through a process of dehydration that you can enter the next step.

2.Next we should use the groove type compost turner. This process is important in the compost fertilizer production. The raw material that can be handled with organic fertilizer turning machine is very extensive. Most of the livestock poop and poultry dung can be handled by this compost turner. Such as chicken poop, pig dung, cow manure. Raw materials need to be fermented and to meet the standards of harmless treatment, so as to further produce commercial organic fertilizer.

3.Then the new type vertical crusher is used. The new type vertical crusher is used for the process to crush. Maybe the raw material has some blocky solid, so it needs to be crushed.

4.The fourth step is to mix the material with horizontal mixer. The purpose of the disc mixer is to mix biological species or NPK evenly.

Granulating

5.Next step is granulation. This process is also the important step in the new type organic fertilizer production line. And of course, we should use new type organic fertilizer granulator to achieve granulation. If you want your organic fertilizer pellets more beautiful and easier to sell. It’s necessary to use this kind of organic fertilizer pellet machine.

6.Drying. The rotary drum drying machine is drying the wet particles.

7. Cooling. The rotary drum cooling machine is to make our organic fertilizer pellets easy to pack.

8.Screening. The rotary screen machine is to screen out unqualified particles and then granulate them again.

9.Single bucket automatic packing scale . The last step is pack the granular fertilizer with the rotary coating machine.

ShunXin Organic Fertilizer Production Line Installed in India

FPD Bio organic fertilizer plant for you to make powdery&granular bio organic fertilizer

In FPD heavy industry technology, we not only have organic fertilizer plant, compound fertilizer plant, but also bio organic fertilizer plant. Generally speaking, bio-organic fertilizer is a kind of fertilizer made by mixing organic fertilizer and microbial agent. Thus, if you want to start a bio fertilizer manufacturing plant, you should prepare the bio organic fertilizer plant raw material, such as, animal poop, agriculture waste, and some microbial agent first. That is the first step.

And then what you need to do is you need to use some bio-organic fertilizer production machines to mix the fertilizer raw material together. These bio organic fertilizer machines for converting organic fertilizer raw material and microbial agent into bio organic fertilizer. Because bio fertilizer doesn’t have the disadvantage of chemical fertilizer, the impacts of bio fertilizer plant to a society is friendly and high-efficiency. In addition, our bio fertilizer plant price is reasonable and affordable.

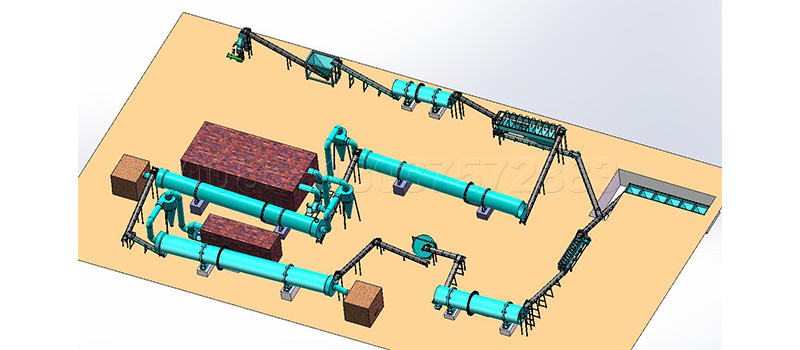

Compound fertilizer production line provided by FPD fertilizer machinery

Except organic fertilizer production line, we also provide compound fertilizer production line for your fertilizer business. Compound fertilizer production line is different from organic fertilizer production line. At the same time, it has different production process.

For making compound fertilizer, we should prepare the compound fertilizer powder in advance. And putting these powder into static batching machine for getting the compound fertilizer powder that has the right proportions.

- Then the compound fertilizer powder can enter the next step-mixing. Through double shafts horizontal mixer, you will get the fertilizer material that mix well.

- By the way, some of the compound fertilizer raw material are lumpy. You should use cage crusher to crush these compound fertilizer materials. And the material will change from lump to powder.

- Next is the process of granulation. This step is the important part of the compound fertilizer production line. For getting the compound fertilizer that beautiful and easy to store. You should use FPD rotary drum granulator to make fertilizer pellets.

- In order to get the packaged granule fertilizer, you also should finish the processes of drying, cooling, screening and packing.

After these processes, you can get the compound fertilizer.

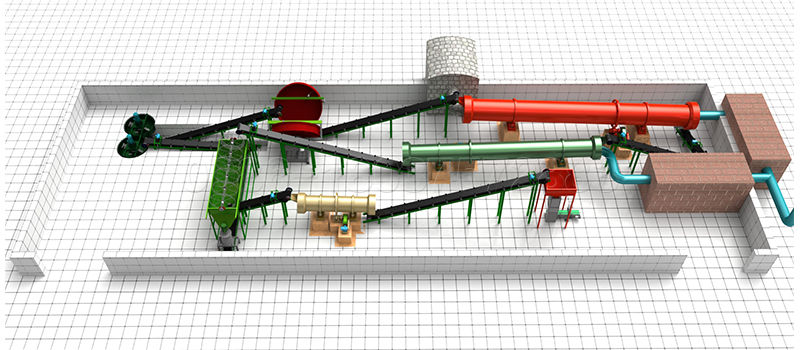

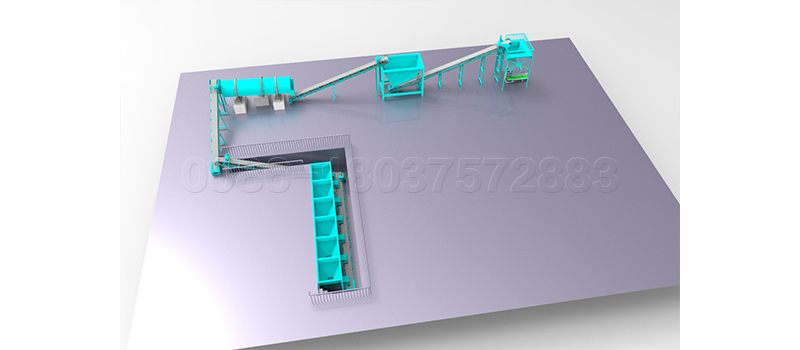

How can you design your fertilizer plant?

If you had a fertilizer plant already, except the fertilizer making equipment, the problem you need to think is fertilizer plant layout. Because the fertilizer facility is important, you need to install the equipment in a reasonable way. Thus, how can you design your fertilizer plant?

- If you have a large-scale fertilize factory, you don’t have to worry about whether you have enough space to install the fertilizer equipment. What you need to consider is how to place the fertilizer equipment in a right way. FPD fertilizer plant designer can help you to solve this problem.

- On the other hand, if you have a small-scale fertilizer company, you’d better know how to save your production space. In FPD heavy industry technology, we have bucket elevator instead of mobile belt conveyor, that will help you save the production space as soon as possible.

- In addition, if you still have some other requirements, please contact with us, we will try our best to solve your problem.

Do you know the main process of making fertilizer ?

Composting process

Composting process is the part of the organic fertilizer production line. And FPD fertilizer plant for sale compost making machine for your fertilizer making . If you want to build a fertilizer plant or organic fertilizer production line, you have to know the composting process. Because there are many harmful microorganisms in raw material. If the organic fertilizer is applied to the farmland directly, that will do harm to your crops. During the composting process, you can use compost making machine to deal with the organic material. With the help of compost making machine, it can convert raw material into fermented fertilizer, which is healthy for your plants and crops. What’s more, it highly improves your compost making efficiency.

Granulating process

Generally speaking, granulating process is the most important part of the fertilizer granulation production line. Generally, after crushing, it is granulating process. The purpose of granulation is to produce fertilizer granules from fine powdery fertilizers. Compared with powdery fertilizer, granular fertilizer is more beautiful and easier to store. To be honest, if you want to get granular fertilizer, you have to use the professional equipment to help you.

In FPD, we have various fertilizer granulators to help you. Such as, new type organic fertilizer granulator, double roller extrusion pellet making machine, rotary drum churning granulator, disc pellet mill, rotary churning granulator. There is an important thing you should know, the machine that makes organic fertilizer pellets is different from the machine that makes compound fertilizer pellets. You should use new type organic fertilizer granulator, disc granulator or rotary drum churning pellet making machine to make organic fertilizer pellets. If you want to make compound granular fertilizer, you should use double roller extrusion granulator, disc granulator or rotary drum pellet making machine.

For building a fertilizer plant, how much money do you need to spend?

There is no doubt that every fertilizer production manufacturer wants to know the cost of setting up a fertilizer plant. In fact, there are many factors that you need to consider.

- The fertilizer production line price. A complete fertilizer production line includes a whole fertilizer making machine. These fertilizer making machines is the most important part to make fertilizer. And the cost of different capacity fertilizer production machine has different price, you need to provide your requirements to your fertilizer machine production manufacturer. Then they will give you the accurate price.

- The cost of fertilizer production site. As we all know, the price of fertilizer site is also the part of the cost of fertilizer plant. If you want to save your fertilizer plant production cost, you can choose the site near the country.

- The cost of fertilizer raw material. For getting the fertilizer what you want, you can’t ignore the fertilizer raw material, such as animal poop, agriculture fertilizer. you need pay some money on it. That means you should find a reliable fertilizer raw material supplier.

FPD fertilizer making machine is sold in India and Europe.

Where can you use the fertilizer made by FPD fertilizer making machine?

The organic fertilizer made by our fertilizer equipment can help various plants grow better. So the application of organic fertilizer is very wide.

- We can use it in the farmland. This is the main application that we came up with. We have mentioned before, there are many benefits if we put organic fertilizer into the farmland.

- In addition, we can also put it into the garden. For example, the rosary. The organic fertilizer will make the flower brighter and more beautiful.

- The organic fertilizer can also be used to the urban landscaping. The trees and grass will be greener by applying organic fertilizer.

Why did our customers choose FPD to make fertilizer equipment for their fertilizer plant?

After-sales service

With over 30 years’ production experience, FPD provides all kinds of organic&compound fertilizer plant for sale. If you want to the find the company which has fertilizer plant for sale. FPD heavy industry technology will be your best choice. We have more than 100 service engineers. They will answer any question that you meet. We will provide you with “15 minutes of quick response, 24 hours completed” service.