The introduction of the organic fertilizer production line

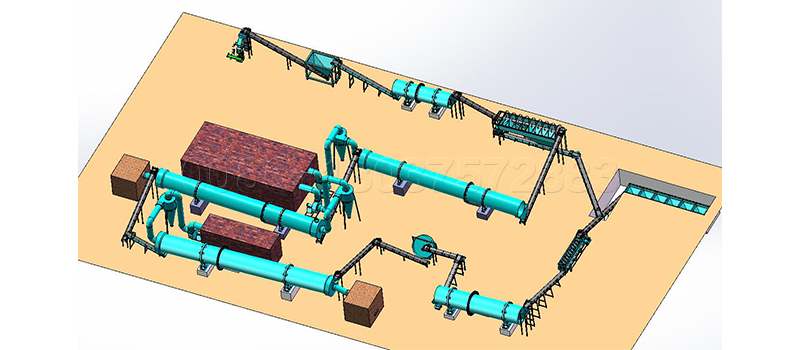

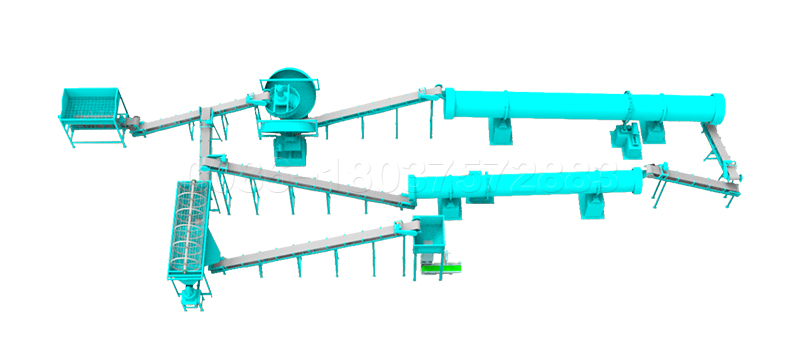

At first, the organic fertilizer production line is a complete production line to make organic fertilizer. With the rapid development of agriculture, a lot of excrement and sewage are produced. But how to deal with it became a serious problem. Because the harmful elements in these poop and sewage exceed the standard seriously. And it is difficult to handle them by the traditional method. According to this situation, people have developed an organic fertilizer production line with movable. What’ more, high-efficiency solid-liquid separation technology as the core and integrated with high-efficiency double shaft mixer, wheel type compost turning machine, new type organic fertilizer granulator, rotary drum cooling machine and other fertilizer production equipment. These facilities are help to convert these waste into organic manure.

High-efficiency small scale organic fertilizer production line provided by SEEC

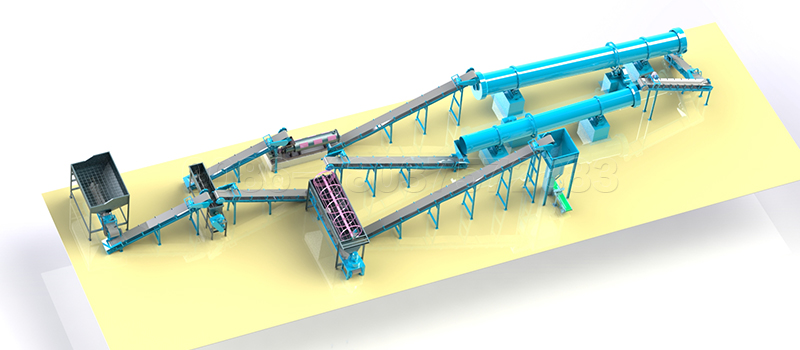

What should to use for a small scale organic fertilizer plant? Actually, a small scale organic fertilizer plant should use small scale organic fertilizer production line. So a small scale organic fertilizer production line is needed. There are many facilities you should use. For example, the small scale chain plate type compost turning machine, small scale new type vertical crusher, small scale disc mixer, small scale rotary drum churning granulator, small scale rotary drum drying machine, small scale vibrating screen machine etc. Our company provides all those organic fertilizer making machines.

Small-scale organic fertilizer pellet mill

- Model: SEECYZ-1800(can be customized)

- Edge height(mm): 300

- Rotary speed(r/min): 21

- Motor power(kw): 3

- Capacity(t/h): 0.8-1.2

- Dimensions: 2060×1700×2130

Bio organic fertilizer production line

In addition to the fertilizer mentioned above., organic fertilizer also includes another fertilizer, that is bio organic fertilizer. Generally speaking, bio organic organic fertilizer refers to the fertilizer which is derived from specific functional microorganisms (microbiological bacteria) and animal and plant residues. For example, these animal residues include sheep poop, chicken poop, pig dung, cattle manure, etc. And plant residues include straw, wood dust and some agriculture wastes. By using specific fertilizer machinery, the bio organic fertilizer raw material will through harmless treatment and fermentation, then you can get the fertilizer with both microbial and organic fertilizer effects. You can click here for more details: bio organic fertilizer production line.

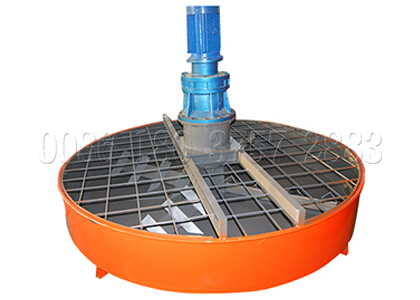

. Mixer for mixing Microbial species and powdery fertilizer

In the bio organic fertilizer production line, fertilizer mixer is the machine that you can’t ignore. Because if you want to get the bio organic fertilizer, you need to mix the powdery organic fertilizer with the microbial species. Then the fertilizer mixer can help you do that.

Pan mixing machine for sale

- Model: SEECPJ-2200

- Edge height(mm): 400

- Disc diameter(mm): 2200

- Motor power(kw): 7.5

- Mixing speed(r/min): 16

- Mixing capacity(t/h): 6-8

How to produce commercial organic fertilizer?

Different companies need different organic fertilizer production line. And if you want to produce commercial organic fertilizer should adopt some big organic fertilizer making machine. Here is the organic fertilizer manufacturing process.

- First you should buy a lot of poultry dung from the livestock farm. The raw material you bought from the livestock farm should not mix the plastics, glass, metals etc. Then you can use chain plate type compost turner to make the material ferment. Raw material only has been fermented can it enter the next process.

- The second step is use our new type vertical crusher to crush the fermented material. This time you should notice that the material must meet the requirement of granulation.

- Granulating. As the most important part of the organic fertilizer production line, you should take this process seriously. And the quality of the organic fertilizer pellet machine should be the best. Our rotary drum churning granulator will be your best choice.

SEEC matural fertilizer granulator

- Model: SEECZJZ-1060

- Production capacity: 5-8 t/h

- Shape size: 7250×1250×1670

- Installation angel: 2°-2.5°

- Total power: 7.5+18.5kw

You also need to finish these steps

- Drying. When the granulation process is finish, the granules are in need of drying. The moisture of organic fertilizer need reduce to 40%. Our rotary drum drying machine will meet your demand.

- Cooling. In order to ensure the granulates quality, the particles needs to go through the cooling process with the help of rotary drum cooling machine. It’ necessary for the process of the organic fertilizer production line.

- Screening. Maybe there are some unqualified granulates during the production. Therefore the vibrating screen machine is needed.

- Packaging. We all know that all the product we use is packaged, and the organic fertilizer pellets also should be packaged. After the last process, then we can sell it.

Organic fertilizer pellets rotary drum screening machine

- Model: SEECGS-1560

- Power(kw): 5.5

- Reducer: ZQ350

- Drum speed: 16

- Screening capacity(t/h): 6-10

How to make your own organic fertilizer?

Due to some people don’t have too much poultry dung, maybe they want to make organic fertilizer with an easy method. They can make a simple organic fertilizer production line. But compared with the machinery equipment the production period will be longer. And how to make organic manure at home?

First you should have poultry poop and waste, you need to collect them in a bin. For instance, vegetable leaves, stalks, peels, fallen leaves, egg shells, tea leaves, coffee grounds, etc. All those waste are useful. And the hay from the yard can also be used for composting. And making organic compost at home need you prepare a compost bin to put the raw material. If you want to get better compost, you should cut up the raw material before to promote the fermentation process. And the bottom of the compost bin should have some holes to help it drain away water. In this way you can make organic manure at home.

The main organic fertilizer manufacturing machine of building organic fertilizer production line.

Groove type compost turner

To be honest, there are many harmful microorganisms existed in the poultry manure. If the raw material applied to the farmland directly, it will lead to burn the seeding. With the help of groove type compost making machine, the fermented fertilizer will not appear this phenomenon. Thus, compost turner is the key machine of the organic fertilizer production process.

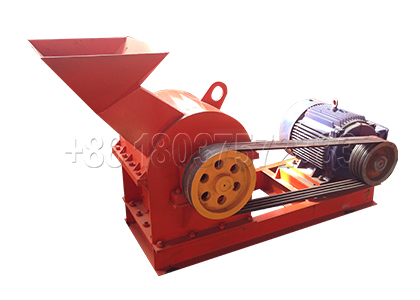

Crusher

After the process of composting, there will be some lumps of fertilizer. If you use hammer crusher, the lumpy fertilizer will turn into powder. And the powdered fertilizers are easier to granulate.

Granulator

If you want to become excellent organic fertilizer manufacturer, you should use new type organic fertilizer granulator. With the help of pellet making machine, you will get high-quality organic fertilizer. and this kind of fertilizer is easier to sell.

How much will it take to operate an organic fertilizer production plant?

If you want to know the cost of the organic fertilizer plant, you should know the price of the organic fertilizer production machine. As mentioned above, if you want to build an organic fertilizer production plant, you should have eight fertilizer making machines. It includes solid-liquid separator machine, organic fertilizer compost turner, organic fertilizer crusher, organic fertilizer pellet making machine, rotary drum drying machine, rotary drum cooling machine, rotary screening machine and single bucket automatic packing scale. With these organic fertilizer making machines, you can build a complete organic fertilizer line to produce organic fertilizer. Then you should know the site and labor costs. By considering these three elements, I’m sure you can calculate the cost of the organic fertilizer factory.

Organic manure drying machine for sale

- Model: SEECHG-2222 (can be customized)

- Power(kw): 37

- Intake temperature(℃): ZQ500

- Inatallation inclination angel(degree): ≥300

- Speed(r/min): 5.5

- Throughput(t/h): 8-16

What materials you can add with organic materials for high-quality fertilizer making?

There are many aspects you can use organic fertilizer production line.

- Poultry waste. Various of animal poop can be processed by an organic fertilizer production line. No matter what dungs you want to process, our organic fertilizer production line will help you.

- Agricultural waste: for example, strew, core stalk, wheat strew, hay and tree leaves etc.

- Household waste: pericarp, vegetable leaves, eggshell and food waste.

- Municipal sludge: domestic sewage, industrial sewage, water supply sludge and river sludge, etc

Organic fertilizer packing machine for sale

- Model: SEEC-50

- Weighing range(kg): 25-50

- Packaging accuracy: per time≤o.2%; Average≤0.1%

- Packaging rate: single weighting: 300-400

- Microscopic index value(kg): 0.01

- Temperature: -10-40°C

How much area consumed for building an organic fertilizer production line?

Before you start your organic fertilizer production line, you should consider the area of the fertilizer production line. Then you can choose the right place to make organic fertilizer. But if you already have an organic fertilizer production plant. You should know how to install the fertilizer equipment in a reasonable way. If you have a small scale fertilizer factory, and the fertilizer production area is limited. SEEC can help you design an installation plan to help you install the fertilizer facilities. For example, a bucket elevator can be used instead of a mobile belt conveyor. That can save your production area.

What factors should be considered in building an organic fertilizer plant?

- First you should consider is how to choose the site of organic fertilizer plant. Then as a businessman, you should choose a place with a low price.

- The second thing you should consider is organic fertilizer plant design. The design of the plant should follow the principle of strong practicality.

- Next your organic fertilizer plant cost also depends on the price of organic fertilizer production line. As mentioned above, you should choose the high-quality organic fertilizer production tool. Only the high quality equipment can reduce maintenance costs.

- The labor cost also is one of the factors what should you consider.

Organic fertilizer production equipment for sale

- Model: SEECLDF-2600(can be customized)

- Durning width(mm): 2600

- Durning height(mm): 1100-1300

- Row spacing(mm): 800-1000

- Working speed(m/min): 6-10

- Capacity (m³/h): 1000-1200

Problems in organic fertilizer production

To be honest, the problem in organic fertilizer production is dust pollution. Dust pollution is the main pollution in the production process of organic fertilizer manufacturers. You need to treat it carefully, there are many links to produce dust pollution.

- When the raw materials are unloaded into the warehouse and transported in different workshops with moving trucks.

- When the compost making machine ferments and flips the raw materials.

- The crusher is crushing the raw materials.

- When you use the rotary drum drying machine and rotary drum cooling machine to process the granulated fertilizer.

So you have to notice this kind of problem. But how to deal with it? In SEEC, we have professional equipment to solve this problem, that is cyclone dust collector and water curtain dust collector. Although the dust is pollution source, but these dust are the raw material that comes from organic fertilizer. After collecting, it can continue to produce organic fertilizer by adding raw material.

The country that can produce the best organic fertilizer production line

You can find many organic fertilizer manufacturers all over the world. But I can say SEEC is the most serious factory. Over 30 years’ production experience, our company had sold many organic fertilizer production lines to many countries, including India and Pakistan. The main project of our company is the production and installation of organic fertilizer production line and its accessories. And the design and construction of the fertilizer engineering. So our professional team can solve every problem what you meet.