Because there are many famers realized that the chemical fertilizer is harm to farmland. The NPK fertilizer is becoming more and more popular in nowadays. With this phenomenon, it’s necessary to build an NPK fertilizer production line if you want to build a fertilizer business. Here are some useful things you need to know.

In order to make NPK fertilizer, do you know the NPK fertilizer production process?

For starting NPK fertilizer production line, you should know the production processes of NPK fertilizer. The following sections we will discuss in depth the NPK fertilizer manufacturing processes.

The main NPK fertilizer production machines

Horizontal mixer

When SEEC horizontal mixer is working during the NPK compound fertilizer production line, the NPK material in the machine is operated by two opposing rotors, and the compound motion is carried out. The horizontal mixer slurry drives the material to rotate counter clockwise along the inner wall of the machine groove. On the one hand, it drives the material to turn around, forming a weightless zone outside the overlap of the two rotors. In this area, no matter the shape, size and density of the material, the NPK material can be floating in an instantaneous weightlessness state. This makes the material in the machine groove form an omni-directional continuous loop, alternating shear, so as to achieve fast and soft mixing uniform effect.

Horizontal mixer for NPK fertilizer production for sale

- Model: SEECWJ-9015(can be customized)

- Demensions(mm): 2350×1200×1000

- Moter power(kw): 11

- Stirring speed(r/min): 39

- Main plate thickness: 4

- Capacity(t/h): 3-5

Double roller extrusion granulator

NPK fertilizer double roller extrusion granulator is the key equipment for compound fertilizer granulation. It has the advantages of advanced technology, reasonable design, compact structure, novelty and utility, low energy consumption. It can support the corresponding equipment, forming a small production line to achieve a certain capacity of continuous, mechanized production.

This kind of fertilizer granules making machine uses eugenics formula. And it can produce at the room temperature without drying. In addition, the product is rolled and formed at one time, so the product quality is in line with the technical requirements of compound fertilizer. The double roller extrusion granulator is used for producing high, medium and low concentration of special compound fertilizer and also is an updated product for energy conservation and consumption reduction in NPK compound fertilizer industry.

This series NPK fertilizer granules making machine, the shape and size of ball socket on the roller sheet can be customized. Thus, we can make pillow shape, semicircle shape, stick shape, pill shape, walnut shape, flat ball shape and square bar shape.

NPK fertilizer double roller extrusion granulator for sale

- Model: SEECWJ-902T(can be customized)

- Power(kw): Granule diameter≤4.5m: 22

- Granule diameter>4.5m: 30

- Granule diameter(mm): 3-10

- Roller sheet size(mm): 185×300

- Diamensions(mm): 1630×850×1650

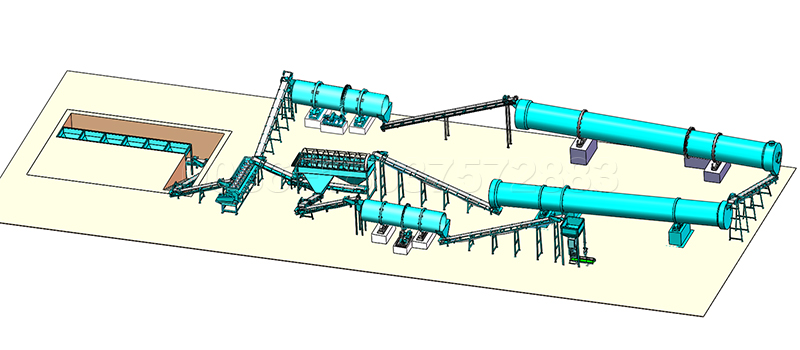

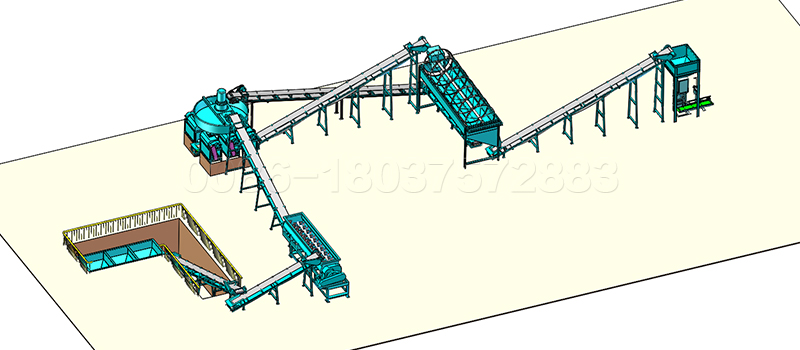

The pictures of NPK fertilizer production machines

The processes of making NPK fertilizer

We all know the NPK fertilizer is a kind of compound fertilizer, so we should mix these chemical elements before you make NPK fertilizer. To be honest you can’t do it by yourself, you should mix these elements with professional equipment. SEEC horizontal mixer will be your good helper. With the help of horizontal mixer, you will get the NPK fertilizer that mix well.

If you want to get the high quality NPK fertilizer, only this one step is not enough. You can make NPK granular fertilizer during the NPK fertilizer production processes. SEEC double roller extrusion granulator will be your best choice. You will get the NPK granular fertilizer what you need by using our pellet making machine.

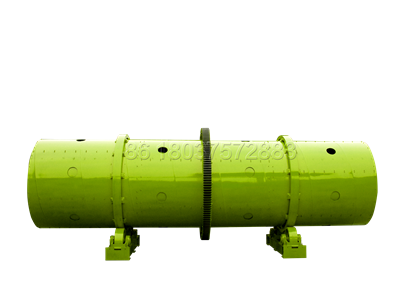

Screening. After these steps, maybe there are some granules not up to the standard of packing. Some are too big and some are too small. You should use rotary screening machine to screen it out and enter the double roller extrusion granulator again.

The last step is packing. With the help of double bucket automatic packing scale, you will get the products as soon as possible.

NPK fertilizer production technology in SEEC fertilizer machinery

In SEEC fertilizer machinery, most of the machines are our patent products. Over 30 years’ production experience, we promise that our patent fertilizer production machine is affordable and high quality.

In addition, we can help you in other aspects. For example, we can help your NPK fertilizer plant design. Our professional staff can help you design suitable installation scheme.

What are the manufacturing process options for NPK fertilizers?

In the NPK fertilizer production line, there are two kind of NPK fertilizer production technology. The first one is dry granulation production technology and wet granulation manufacturing process. And every granulation method has their advantage.

Dry granulation manufacturing process. In the dry granulation process, the main NPK fertilizer making machine in the dry granulation manufacturing process is double roller extrusion pelletizer. By using NPK fertilizer double roller extrusion pellet mill, you don’t need to use drying machine and cooling machine any more. The hardness of particles is higher than that produced by other ball making machines.

Wet granulation manufacturing process. The main NPK granular fertilizer granulator in wet granulation manufacturing process is disk granulator. The advantage of disc pelletizer is good fluidity and density. In addition, because the granulation process involves liquid, so no dust is produced and no air pollution is caused. And the price is lower than double roller extrusion granulator.

With these two different NPK fertilizer granulation technology, you can choose the suitable NPK fertilizer production process for your NPK compound fertilizer manufacturing process.

If you want to be a NPK fertilizer manufacturer, what things you should to know?

If you want to become an NPK fertilizer manufacturer in your country, there are some things you need to know.

For example, if you want to be an NPK fertilizer manufacturer in india, you should know the price of NPK fertilizer and the NPK fertilizer manufacturer around you. As the Chinese saying goes, “know the enemy and know yourself, and you can fight a hundred battles with no danger of defeat”.

In addition, you also should to know the market. Are there any people want to buy the NPK fertilizer? How many places can you sell your NPK fertilizer? do you want to sell the NPK fertilizer abroad?

What’s the NPK fertilizer plant cost?

Starting a NPK fertilizer production line will need you much money. So what is the production cost of NPK blending fertilizer? Here are the aspects of NPK fertilizer production process cost.

First, you should have a place to build an NPK fertilizer production line. If you have enough money, you can buy a place to build it. Or not, you can rent a place to start your NPK fertilizer business.

Then we can enter the important part of the NPK fertilizer production processes. That is the machine. As mentioned above, you need horizontal mixer, double roller extrusion granulator, rotary screening machine, double bucket automatic packing scale to help you finish your NPK fertilizer production. SEEC have produced those NPK fertilizer machines for many years. If you need these machines, feel free to contact us. And we will provide the suitable machine what you need.

Then you also need to consider the address of your factory. We know the place near the city will be more expensive. So you had better choose a place where is far from the city.

What are the raw materials required for production of NPK fertilizer?

Generally speaking, there are many elements can be used to make NPK fertilizer during the NPK fertilizer production line.

Firstly, the raw materials of nitrogen fertilizer production are coal and natural gas, including urea, ammonium bicarbonate, ammonium chloride, ammonium sulfate, ammonium nitrate and calcium cyanamide. These elements are good raw materials to produce NPK fertilizer.

The main raw materials of phosphate fertilizer production are phosphate ore and sulfuric acid

What is the preparatory work for a NPK fertilizer production line?

For getting NPK fertilizer, what should you prepare before you make set up a NPK fertilizer production line? Here are some things that you should notice.

The first thing is the material. If you want to get NPK fertilizer, you had better prepare the fertilizer material first. As noted above, the NPK fertilizer material include urea, ammonium chloride, calcium nitrate, ammonium sulfate, monoammonium phosphate, diammonium phosphate, calcium magnesium phosphate and triple suprphosphate and so on.

Do a market research. If you want to become the best NPK fertilizer manufacturer, it’s necessary for you to know the NPK fertilizer factories around you. Thus, you need to do a market research. That can help you have a clear production plan.

Choose a good fertilizer machinery manufacturer. As we all know, the NPK fertilizer making machine is important in the NPK fertilizer production line. So, you should find a reliable NPK fertilizer machinery manufacturer.

The importance of Chicken manure fertilizer in NPK fertilizer production line

Because chicken manure is high in nitrogen element. So the chicken poop can be added to the NPK fertilizer production. With the help of chicken manure, you only need to add the phosphorus and potassium. Chicken manure as a kind of organic fertilizer, it can be made chicken poop compost. In SEEC, our fertilizer making machine can make various organic fertilizer by using organic material. Such as, pig manure, vermicompost, cattle manure, horse manure, sheep manure, sludge and garbage etc.

Organic waste turning machine for sale

- Model: SEECLDF-2600(can be customized)

- Durning width(mm): 2600

- Durning height(mm): 1100-1300

- Row spacing(mm): 800-1000

- Working speed(m/min): 6-10

- Capacity (m³/h): 1000-1200

Are there any effects on NPK fertilizer on coriander seed and yield production?

Nitrogen fertilizer can be used to judge the nitrogen supply from leaf area and leaf color. In the seedling stage, the general plant nitrogen deficiency is manifested as slow growth, stunted plants, thin and small leaves, green and yellow leaves. Nitrogen fertilizer has obvious effect on promoting plant growth and health. And potassium fertilizer can enhance the tolerance of plants to various adverse conditions, such as drought, low temperature, salt content, disease and insect damage, lodging, etc.

Phosphorus can promote the formation and growth of early root system. Improving the ability of plants to adapt the external environmental conditions, and help plants withstand the cold winter.

If the crops are short of phosphorus, it will lead to plant dark green, and sometimes are red or purple, dark green when dry. In addition, it also will lead to the characters of stem short and thin, leaf base yellow, flower lately, seeds small.

Lack of potassium: the old leaves turn yellow along the leaf edge, and the leaf edges appear to be burning when severe.

So if the coriander seed has these phenomenon, it’s necessary to use NPK fertilizer. and starting an NPK fertilizer production line will bring in a tidy profit for you.

Plate fertilizer granulator for sale

- Model: SEECYZ-3000(can be customized)

- Edge height(mm): 450

- Rotary speed: 14

- Motor power(kw): 11

- Capacity(t/h): 2-4

- Dimensions: 3400×2400×3100

Application of NPK fertilizer production line

To be honest, the process of NPK fertilizer production is also the process of granulating. As mentioned above, you will know SEEC has different fertilizer manufacturing process. In addition, our NPK fertilizer production line has a wide application, such as, mineral processing, food processing, agriculture, detergent chemistry, pharmaceutical enterprises, especially in fertilizer factories. In addition, our fertilizer production line is designed on advanced theory. The granulation method is attractive in terms of cost-effectiveness in light of low investment and exploitation expenses. Thus, in these industries, our fertilizer production line can do it better.

When you start an NPK fertilizer business, how much NPK fertilizer production line spaces do you need?

Generally speaking, for building an NPK fertilizer production line also like compound fertilizer production line, it also need raw materials like stacking area, fermentation workshop, equipment storage area, processing workshop, semi-finished products storage area, finished products warehouse, office area, staff living area and planting demonstration area. So you have to consider many factors. If you don’t want to consider too much, SEEC’s professionals can give you many useful suggestions.

Because different factory has different situation. SEEC’s experts can help to design different project according your needs.

For example, if you have a factory with 700 square meters. You had better to build a NPK fertilizer production line with 10000 tons per year. And if you want to know more information, feel free to send an email to us.

NPK Compound Fertilizer Production Line Finished Installation in Uzbekistan