What is dehydration?

Generally speaking, if you have some cow dung in your farm, you can find that there is too much moisture existed in the cow poop. In fact, you can’t make cow manure fertilizer with the cow poop has too much moisture. Because there are lots of pathogens and bacteria in the cow manure raw material. In order to get safe cow manure fertilizer, you had better remove the moisture from the cattle poop. The process of removing water means dehydration. This the first step in manure treatment process. In our fertilizer machinery, we have scientific solid liquid separation machine can help you do that.

The equipment for removing the moisture of cattle manure

In cow manure fertilizer making process, cow manure dewatering machine is the first machine that you should use. As mentioned, you know cow manure dehydrator can help you remove the moisture of cow poop. And cow manure dewatering machine has another name, that is solid-liquid separator machine. Our cow manure solid liquid separation machine not only can deal with cow dung, but also can dispose other organic fertilizer, such as, sheep poop, horse dung, pig dung, sludge etc. What’s more, you can also use our fertilizer raw material separator machine in pharmaceutical industry. If you want to get high quality cow manure fertilizer, the moisture of cow poop should be controlled in 40%-65%.

And how do you know if the moisture is right? The method is you can put some fertilizer into your hand, then hold the cow manure fertilizer. If you see the watermark on the fingertips but do not drip. That means you get the cow manure fertilizer with the suitable moisture. By using cow manure dewatering machine, then you can enter the nest processs.

What is the cow dung dewatering technology in the cow manure wastewater treatment process?

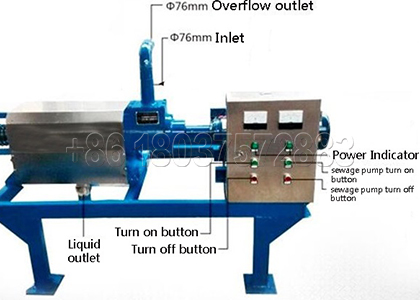

With the help of organic fertilizer solid-liquid separator machine, you can get the cow manure with suitable moisture content. For making cow manure fertilizer, you’d better to know the cow wastewater treatment process. And here is the system of cow manure separator machine.

At first, the cow dung raw material is pumped to the cow manure dewatering machine by the supporting non-blocking liquid pump, and then the cow dung water is gradually pushed to the front of the machine by the auger. At the same time, the pressure at the leading edge of the machine is continuously increased to force the water in the cow manure to extrude from the mesh screen, and the water will be flow out of the drain pipe under the action of the edge pressure belt filter. The work of the cow manure dehydrator is continuous. The cow manure water is continuously promoted to the body of the cow manure dehydrator, and the pressure on the leading edge keeps increasing. When the pressure reaches a certain level, the manure will come out of the discharge mouth.

In order to know the discharging speed and moisture content, you can adjust the counterweight block under the main engine to achieve a satisfactory discharging state. In addition, If the cow manure raw material is too much, it will discharge through the overflow pipe to the original cow manure pool.

This is our solid liquid separation method, after reading this paragraph, you can know our solid liquid separator design is reasonable and advanced.

With the help of cow manure dewatering machine, how to make powdery cow manure organic fertilizer?

For getting cow manure fertilizer, you only have a cow manure separator equipment is not enough. You should have some other cow dung fertilizer machines to help you make powdery cow manure organic fertilizer. In cow manure fertilizer production line, there is a machine that you can’t ignore. This is cow manure windrow turner. Windrow turning machine is the main fertilizer making machine in organic fertilizer production line. In fact, with the help of cow manure separator equipment and compost manure making machine, you will get the powdery cow manure organic fertilizer in a short time. Our powdery cow manure processing machine uses an oxygen-consuming fermentation process to make organic fertilizer. And it has the character of stir and crush. With this special working principle, cow manure fertilizer can be fully fermented.

In the powdery cow manure fertilizer making process, if you want to get perfect powdery cow manure fertilizer, you had better use another manure equipment-cow manure fertilizer crusher. Although cow manure compost turning machine has the character of crush, it still has some lumpy fertilizer. In order to get better powdery fertilizer, you need a crusher to help you.

What is the price of cow manure dewatering machine?

In our cow manure fertilizer machinery, you can get different types of cow manure solid-liquid separator machines. At the same time, different cow dung dewatering machine price is also different. The filter screen and spiral blade of cow manure dehydrator are made of high quality 304 stainless steel alloy. And the dehydrator is manufactured by special technology and has the characteristics of better corrosion resistance and wear resistance. On the contrary, other fertilizer raw material dehydrators that do not use these superior materials are cheaper. You can choose the suitable cow manure dewatering equipment for composting cow manure .

Cow manure separator for sale

Where can our cow manure dehydrator be used?

Our cow manure dehydrator has wide application, you can use it in many places.

Farm. On most farms, there are many organic raw materials has too much moisture content, and you can make organic compost fertilizer with the organic farm waste. In this way, cow manure fertilizer solid-liquid separator can help you save a lot of money.

Cow dung fertilizer production plant. For getting high-efficiency cow manure fertilizer, you need a manure equipment to dispose the moisture in the cow dung. As a cow dung manure supplier, you had better have a cow manure fertilizer dewatering machine,

Cow dung wastewater treatment plant. Of course, you can also buy a cow manure dewatering machine for your cow poop wastewater treatment plant. Then you can sell the cow manure fertilizer to fertilizer production plant.