Bio organic fertilizer is a kind of fertilizer that can be applied to the crops and plants. And it has the characters of both microbial fertilizer and organic fertilizer effect. The main source of bioorganic fertilizer was animal manure and plant bio fertilizer. Such as livestock and poultry manure, crop straw, etc. If you want to get high-quality bio organic fertilizer, these animal manure and crop straw must be innocent treatment and decomposed.

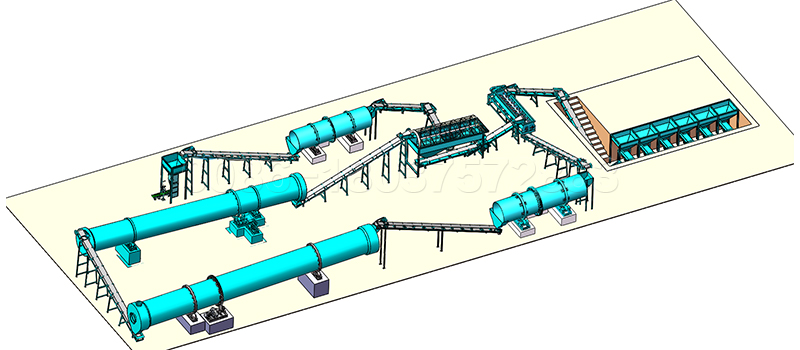

The bio fertilizer manufacturing process is provided for making bio organic fertilizer

Starting a bio organic fertilizer production line, here are the biofertilizer production processes you should know. We know bio-organic fertilizer is a kind of green and nutrient-rich compound microbial fertilizer, which is produced by the mixed fermentation of livestock manure, organic matter and microbial species. And the addition of appropriate amount of humic acid, trace elements and microbial bacteria.

Steps to make bio fertilizer

- First you have to prepare some organic material, such as poultry manure, straw, sludge and garbage, filter mud from sugar mill, worse slag cake and other organic waste. You also need to prepare the humic acid and microbial bacteria for use.

- The animal manure has too much moisture. In the bio organic fertilizer production line, the first thing you need to know is to dehydrate the manure.

- Then you need to do is to ferment these organic materials. SEEC provides all kinds of compost turner for your need. SEEC compost production machine will help you make organic fertilizer as soon as possible. Through compost turner, it only takes you 20 days to get organic fertilizer.

- The bio organic fertilizer should mix with humic acid, trace elements and microbial bacteria. So you need to use SEEC static batching machine to finish this process. By using static batching machine will greatly save time and production cost.

- Next step is mixing. In order to make the materials evenly mixed together, you should use double shafts horizontal mixer to help you.

- If you want to get bio organic fertilizer pellets, SEEC rotary drum stirring granulator will be your best choice. In the process of bio organic fertilizer production, the pellet making machine is indispensable. With the help of granulator, you will get beautiful pellets that is easy to store.

- In order to finish the biofertilizer production project, you also need to use rotary drum drying machine, rotary cooling machine, rotary screening machine and double bucket automatic packing machine to help you.

Bio organic fertilizer pelletizer for sale

- Model: SEECYZ-3000(can be customized)

- Edge height(mm): 450

- Rotary speed(r/min): 14

- Motor power(kw): 11

- Capacity(t/h): 2-4

- Dimensions: 3400×2400×3100

Besides bio fertilizer compost turner, what other bio-organic fertilizer fermentation equipment can promote bio-fertilizer fermentation

In the process of bio organic fertilizer production process, you can get the powdery bio organic fertilizer by using compost turner. But except compost fertilizer turning machine, what other fermentation equipment that you can replace. In SEEC heavy industry technology, you can also use a fertilizer fermenter for producing biofertilizer. After the process of crushing, then you can put the bio organic fertilizer raw material into the bio fertilizer fermenter. By using fermentation tank you will get the fermented bio organic fertilizer in 7-10days. It can save you more money than compost turner. and the quality of fertilizer will be better.

. The advantages of bio organic fertilizer fermentation tank

Our fermenter tank has the character of full automatic automation, high closure and no secondary pollution.

This bio organic fertilizer adopts vertical closed tank structure, which saves the floor space and reduces the requirement of equipment installation.

The bio organic fertilizer fermentation vessel is made of 304 stainless steel, which is corrosion-proof and has a long service life.

The machine operation is fully automated, and the fermenter can realize the unmanned operating system.

The inside of the fermentation tank is made of polyurethane insulation layer, which is less affected by the outside world and ensures the fermentation all year round.

Bio organic fertilizer fermentation tanks for sale

- Model: SEECFJG-10

- Heating power(kw): 4×6

- Stirring power(kw): 11

- Reducer model: BLED85-493-11

- Stirring speed(r/min): 3

- Overall size: 2400×2400×6900

How to start a biofertilizer company?

- First you should have a factory to build a bio organic fertilizer production line. As bio fertilizer plant manufacturers, it’s necessary to have a personal place. Starting a bio organic fertilizer business, you should consider the bio fertilizer plant cost. For more profits, you can choose a place far from downtown.

- Next is the important point, if you want to build a bio organic fertilizer production line, you have to have specific machines to produce bio organic fertilizer. Such as, fertilizer crusher, organic fertilizer compost turner, fertilizer granulator, etc. SEEC fertilizer machinery can provide it for you.

- The last point is the government support. Different country has different policy, you should follow the relevant law and local government requirements.

Bentonite fertilizer granulating machine for sale

- Model: SEECZJZ-1060

- Production capacity: 5-8 t/h

- Shape size: 7250×1250×1670

- Installation angel: 2°-2.5°

- Total power: 7.5+18.5kw

When should you add microbial bacteria?

If you start a bio organic fertilizer pellets production plant, you have to add some microbial bacteria. Do you know when should you add microbial bacteria?

You can add the microbial bacteria before the granulation process. By using static batching machine, you can get the well mixed material.

If your microbial bacteria are liquid, you can coat the organic fertilizer granules with liquid microbial bacteria with a rotary coating machine.

So there are two ways to add microbes, and you can do whatever you like.

When the bio organic fertilizer applied to the crops, what things do you need to notice?

If you have a biofertilizer company, there are some things you should know.

The bio organic fertilizer should not be used with pesticide. If pesticide is applied, the bio organic fertilizer must be applied after 48 hours. Storing bio organic fertilizer in a cool, ventilated, dry place and should not exposed to the sun.

During the fermentation process, you’d better guarantee the time of fermentation. If farmer apply the bio organic fertilizer that not fully fermented, will cause the effect of burning seedlings.

New type compost pellet machine for your Bio organic fertilizer

- Model: (can be customized)

- Installation angel: 2°-2.5°

- Capacity(t/h): 4-6

- Total power(kw): 90

- Moisture of feeding material: 20%-40%

How to create a globally competitive bio organic fertilizer company?

There are many bio fertilizer production units in the world. Do you want to become the excellent one? The necessary addition of becoming a good bio organic company is to have the biofertilizer production technology. That means you should have good bio organic fertilizer production machines in your bio organic fertilizer production line. As chinese best fertilizer equipment manufacturer, SEEC has the best bio organic fertilizer facilities. With the help of SEEC fertilizer equipment, you will get the high-quality bio organic fertilizer. And getting a huge profit from it.

For starting a fertilizer plant, how to achieve mass production of bio organic fertilizers?

If you want to build a fertilizer plant in your own country, there are some things you should know.

You should have a clear sense of the biofertilizer production and quality control. You should know how much fertilizer you want to produce in an hour. Or you can also tell us what kind of fertilizer you want. Powder fertilizer or granulator fertilizer? Then we will tell you what kind of production line you need to use.

For example, if you want to get powder fertilizer, you should at least have a crusher and a compost turner. After the process of fermentation, you will get the powder fertilizer. On the contrary, if you want to get granules fertilizer, you should have crusher, compost making machine, granulator (pellet making machine), packing machine at least. In addition, we have mentioned the biofertilizer production process, you can find the things you want to know.

Commercial production means large-scale production, you need have some large-scale bio fertilizer production equipment. You can get 6t-8t bio fertilizer in one hour by using our bio organic fertilizer rotary drum churning granulator. And if you want to start a large scale production of biofertilizers, we can provide the production line with large scale for you.

Market potential of bio organic fertilizer business

Because the environment problem became more and more important, and the need for chemical fertilizer is becoming less and less. People want to find a fertilizer that is both eco-friendly and good for the crops. With this kind of needs, bio fertilizer will be a good business. If you want to start a business, starting a bio organic fertilizer production line will bring you great profits. Because the production investment is little, raw material is easy to get. In addition, the cost is low. With the promotion of bio-organic fertilizer in global ecological agriculture, farmers have got a basic understanding and recognition of it. Global agricultural markets for biological organic fertilizer demand will continue to increase. Therefore, the production of bio-organic fertilizer will become a potential business opportunity and an urgent trend.