Kasama ang pag -unlad ng ekonomiya, Parami nang parami ang natanto ng kahalagahan ng proteksyon sa kapaligiran. Lalo na sa lupain, Karamihan sa tao ay nais na makahanap ng isang eco-friendly na pataba para sa kanilang mga pananim. Sa gayon, Ang organikong pataba ay nagiging popular. Ayon sa sitwasyong ito, Maraming mga tagagawa ng pataba ang nais na magsimula ng isang organikong halaman ng produksyon ng pataba upang makabuo ng organikong pataba. Ang FPD ay may pinaka -angkop Kagamitan sa Fertilizer ng Organic, at ang aming halaman ng pataba na ibinebenta sa iyong kahilingan.

Anong uri ng linya ng produksyon ng pataba na ibinigay ng Shunxin Fertilizer Plant Dsigner?

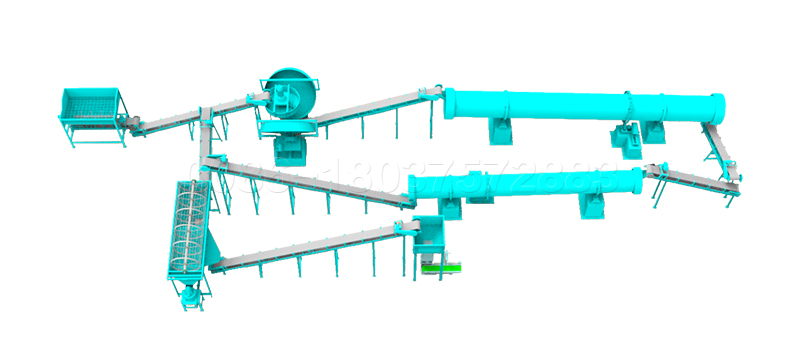

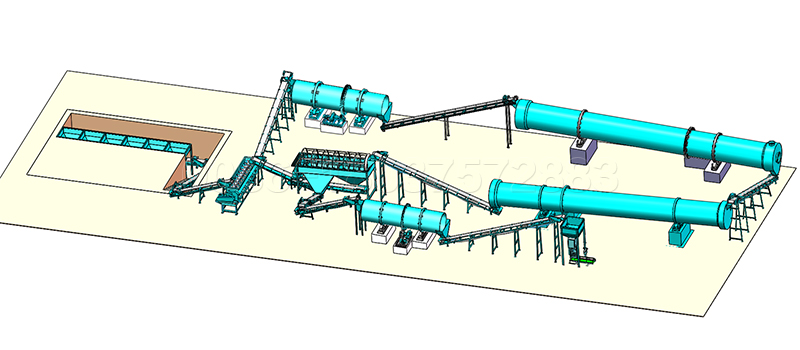

Ang buong linya ng produksiyon ng organikong pataba para ibenta

FPD Organic Fertilizer Production Line ay isa sa mga pangunahing linya ng produksiyon ng pataba. Dito maaari mong malaman ang proseso ng paggawa ng linya ng produksyon ng organikong pataba.

1. Una dapat mong ihanda ang hilaw na materyal na nais mong gumawa ng organikong pataba . Tulad ng, Livestock manure, putik at basura, I -filter ang putik mula sa mill mill, mas masahol na slag cake at dayami na sawdust at iba pang mga basurang basura . Ang mga hilaw na materyal na ito ay hindi dapat ihalo sa plastik, baso, metal atbp. Pagkatapos ay maaari mong gamitin ang chain plate type compost turner upang gawin ang materyal na pagbuburo.

2.Susunod, Dapat mong gamitin ang aming bagong uri ng vertical crusher upang durugin ang ferment material. Dapat mong mapansin na ang organikong materyal ay dapat matugunan ang kahilingan ng butil.

3.Granulate. Bilang pinakamahalagang bahagi ng linya ng produksyon ng organikong pataba, Dapat mong seryosohin ang prosesong ito. At ang kalidad ng Organic Fertilizer Pellet Machine dapat ang pinakamahusay. Ang aming Fertilizer Plant Para sa Pagbebenta Rotary Drum Pagpukaw ng Granulator Upang Gumawa ng Mga Pellets ng Fertilizer.

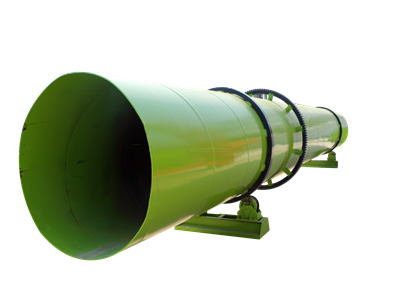

4.Pagpapatayo. Pagkatapos ng granulate, Ang nilalaman ng kahalumigmigan ng organikong pataba ay masyadong mataas upang mag -pack. Mas mahusay kang gumamit ng isang rotary drum dryer para sa pagbaba ng pelleted na organikong nilalaman ng kahalumigmigan ng mga pataba.

5.Paglamig. Upang matiyak ang kalidad ng mga pellets, Ang mga particle ay dapat na pinalamig pagkatapos ng pagpapatayo sa tulong ng rotary drum cooling machine. Kinakailangan para sa proseso ng linya ng produksyon ng organikong pataba.

6.Screening. Marahil ay may ilang mga hindi kwalipikadong butil na pataba sa panahon ng paggawa. Samakatuwid, Kailangan ang vibrating screen machine.

7.Packaging. Alam nating lahat na ang lahat ng produktong ginagamit namin ay nakabalot, at ang mga organikong pellets ng pataba ay dapat ding nakabalot.

Ang linya ng produksyon ng butil ng pataba para sa pagbebenta

Ang produksiyon ng butil ng pataba ay katulad ng proseso ng paggawa ng pataba. Narito ang linya ng produksyon ng butil ng pataba.

- Upang makagawa ng butil na pataba, Kailangan mong ihanda muna ang pulbos na pataba.

- Pagkatapos ay maaari mong ipasok ang proseso ng granulate. Bilang mahalagang bahagi ng linya ng produksiyon, Dapat nating gamitin ang fertilizer granulator machine sa butil. Pagkatapos ng prosesong ito, Maaari kaming makakuha ng magagandang organikong mga pellets.

- Ang rotary drum drying machine at rotary drum cooling machine ay gagawa ng mga organikong pellets na matugunan ang mga kinakailangan ng packaging.

- Ang rotary screen machine ay mag -screen out ng hindi kwalipikadong mga pellets at kwalipikadong pellet para sa pagpasok sa susunod na hakbang.

- Pag -iimpake. Ang packing machine ay makakatulong upang i -pack ang mga organikong pellets ng pataba. Mayroon kaming iba't ibang mga packing machine. Tulad ng solong bucket awtomatikong pag -iimpake scale, Double Bucket Awtomatikong Packing Scale at Walang Bucket Awtomatikong Salu -Packing Scale. Kung mayroon kang isang malaking linya ng produksyon ng pataba, Maaari mong piliin ang Double Bucket Awtomatikong Packing Scale.

Iyon ang buong linya ng produksyon ng butil ng pataba. Kung nais mong bumuo ng isang halaman ng butil ng pataba, Ito ay kapaki -pakinabang para sa iyong proyekto.

Ano ang dapat mong malaman kapag pumipili ng isang site para sa isang halaman ng pataba?

Pangkalahatang nagsasalita, Dapat kang pumili ng isang magandang lugar sa Product Organic Fertilizer at Compound Fertilizer. Narito ang mga kinakailangan ng pagbuo ng isang halaman ng pataba.

- Ang mga halaman ay dapat na matatagpuan malapit sa supply ng mga hilaw na materyales at gasolina. Dapat din itong pumili ng mga lugar na may magagandang kondisyon para sa kooperasyon sa imbakan, transportasyon, Pag -aayos ng makina, pampublikong gawa at mga pasilidad sa pamumuhay.

- Ang site ng pabrika ay dapat malapit sa lugar na may sapat na tubig, Magandang kalidad ng tubig at sapat na supply ng kuryente. Sa mga kondisyong ito, Ang kagamitan sa paggawa ng pataba ay maaaring gumana nang maayos.

- At ang site ng pabrika ay dapat mapili sa isang maginhawang lugar ng transportasyon.

- Ang pagpili ng halaman ng pataba ay dapat magbayad ng pansin sa pag -save ng lupa, Huwag sakupin o sakupin ang mas kaunting maaasahang lupain. Ang iyong lugar ng pataba at hugis ng lugar ng halaman ay dapat matugunan ang mga pangangailangan ng makatuwirang layout ng daloy ng proseso. Bilang karagdagan, Dapat mayroong silid para sa naaangkop na pag -unlad.

- Matapos ang pagpapatakbo ng pabrika ng pataba, Ito ay gagawa ng isang paunang pagsusuri ng epekto na dulot ng nakapaligid na kapaligiran

Apat na mga uri ng halaman ng Hot Sale Fertilizer na ibinebenta

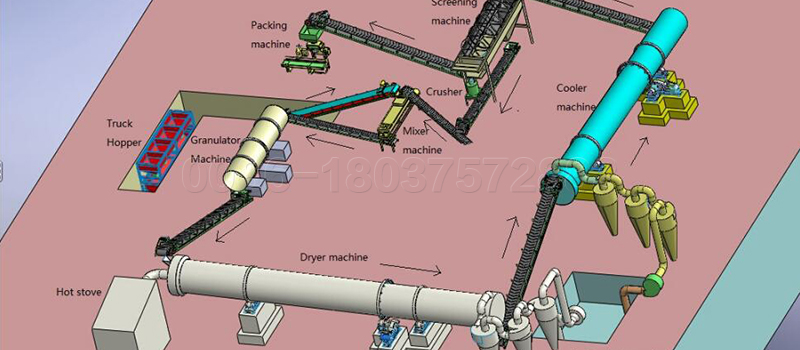

Ang proseso ng butil ng halaman ng pataba na butil

- Paghaluin ang mga kwalipikadong hilaw na materyales sa isang mataas na kahusayan ng panghalo ayon sa mga kinakailangan sa pagtutugma.

- Pagkatapos ay dalhin ang mga hilaw na materyales sa tray feeder upang alisin ang nilalaman ng bakal sa materyal sa panahon ng proseso ng paghahatid.

- Kapag ang materyal ay pumapasok sa rotary drum churning granulator na pantay sa disc feeder, Ang materyal ay mapipilitang pumasa sa pagitan ng dalawang mga rolyo ng presyon at extruded sa isang sheet. At ang sheet ay pinindot ng isang magaspang na pandurog sa ilalim ng isang pressure roller na nahati sa mga piraso at pagkatapos ay sieved, Ang materyal sa screen ay patuloy na nasira at naka -screen.

- Susunod, Pagdala ng semi-tapos na produkto sa natapos na machine screening machine. Ang pinong mga particle pagkatapos ng screening ay direktang ibabalik sa tray feeder. Ang hindi kwalipikadong mga pellets ay durog ng pandurog ng hawla at bumalik sa disc feeder.

- Pagkatapos ng screening, Ang mga kwalipikadong produkto ay tatanggalin sa nag -iisang bucket awtomatikong scale ng packaging para sa pagtimbang, packaging at tindahan.

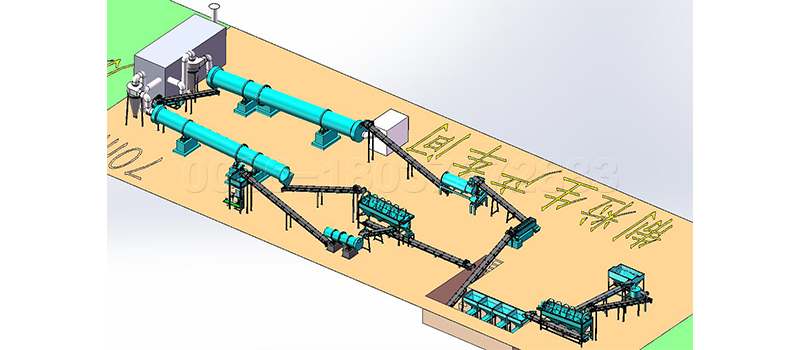

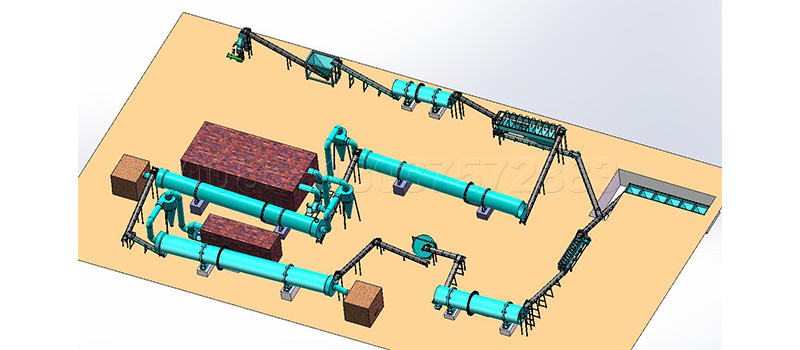

Ang linya ng produksyon ng FPD Compost Fertilizer para sa iyong halaman ng pataba

FPD Organic Fertilizer Plant Para sa Pagbebenta

1.Ang unang hakbang na dapat mong gamitin ang solid-liquid separator machine upang ma-dehydrate ang hilaw na materyal. Bago mo gamitin ang hilaw na materyal para sa paggawa ng compost, Dapat kang dumaan sa isang proseso ng pag -aalis ng tubig na maaari mong ipasok ang susunod na hakbang.

2.Susunod dapat nating gamitin ang uri ng Groove Type Compost. Mahalaga ang prosesong ito sa Produksyon ng Fertilizer ng Compost. Ang hilaw na materyal na maaaring hawakan ng organikong pataba ng pataba ay napakalawak. Karamihan sa mga hayop ng hayop at manok ng manok ay maaaring hawakan ng compost turner na ito. Tulad ng tae ng manok, Baboy Dung, pataba ng baka. Ang mga hilaw na materyales ay kailangang ma -ferment at upang matugunan ang mga pamantayan ng hindi nakakapinsalang paggamot, upang higit na makabuo ng komersyal na organikong pataba.

3.Pagkatapos ay ginagamit ang bagong uri ng vertical crusher. Ang bagong uri ng vertical crusher ay ginagamit para sa proseso upang madurog. Marahil ang hilaw na materyal ay may ilang blocky solid, Kaya kailangan itong madurog.

4.Ang ika -apat na hakbang ay upang paghaluin ang materyal na may pahalang na panghalo. Ang layunin ng panghalo ng disc ay upang paghaluin ang mga biological species o NPK nang pantay -pantay.

Granulate

5.Susunod na hakbang ay ang butil. Ang prosesong ito ay din ang mahalagang hakbang sa bagong uri ng linya ng produksyon ng pataba. At syempre, Dapat nating gamitin Bagong Uri ng Organic Fertilizer Granulator Upang makamit ang butil. Kung nais mo ang iyong mga organikong pellets ng pataba na mas maganda at mas madaling ibenta. Kinakailangan na gamitin ang ganitong uri ng organikong pataba na pellet machine.

6.Pagpapatayo. Ang rotary drum drying machine ay pinatuyo ang basa na mga particle.

7. Paglamig. Ang rotary drum cooling machine ay upang gawing madaling i -pack ang aming mga organikong pellets.

8.Screening. Ang rotary screen machine ay upang i -screen out ang hindi kwalipikadong mga particle at pagkatapos ay muling mabighani ang mga ito.

9.Single bucket awtomatikong packing scale . Ang huling hakbang ay i -pack ang butil na pataba na may rotary coating machine.

Shunxin Organic Fertilizer Production Line na naka -install sa India

FPD Bio Organic Fertilizer Plant para makagawa ka ng pulbos&Granular Bio Organic Fertilizer

Sa teknolohiyang mabibigat na industriya ng FPD, Hindi lamang kami may organikong halaman ng pataba, Compound Fertilizer Plant, ngunit din Bio Organic Fertilizer Plant. Pangkalahatang nagsasalita, Ang Bio-Organic Fertilizer ay isang uri ng pataba na ginawa sa pamamagitan ng paghahalo ng organikong pataba at microbial agent. Sa gayon, Kung nais mong magsimula ng isang planta ng pagmamanupaktura ng bio fertilizer, Dapat mong ihanda ang halaman ng Bio Organic Fertilizer Raw Material, tulad ng, Animal Poop, basura ng agrikultura, at ilang microbial agent muna. Iyon ang unang hakbang.

At pagkatapos kung ano ang kailangan mong gawin ay kailangan mong gumamit ng ilang mga makina ng produksyon ng bio-organikong pataba upang ihalo ang hilaw na materyal na pataba. Ang mga Bio Organic Fertilizer Machines para sa Pag -convert ng Organic Fertilizer Raw Material at Microbial Agent sa Bio Organic Fertilizer. Dahil ang Bio Fertilizer ay walang kawalan ng kemikal na pataba, Ang mga epekto ng halaman ng pataba ng bio sa isang lipunan ay palakaibigan at mataas na kahusayan. Bilang karagdagan, Ang aming presyo ng halaman ng pataba ng bio ay makatwiran at abot -kayang.

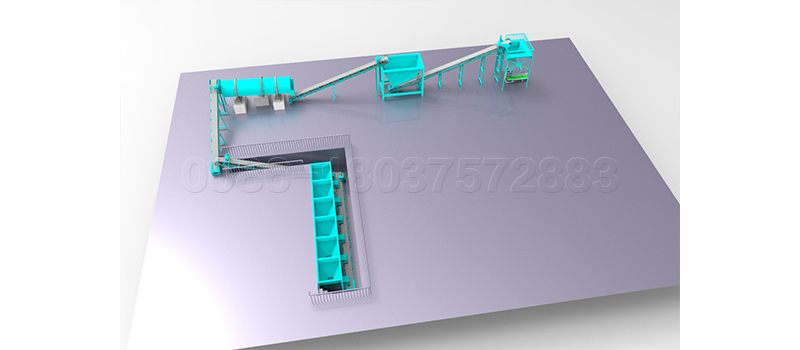

Compound na linya ng produksyon ng pataba na ibinigay ng makinarya ng FPD Fertilizer

Maliban sa linya ng produksiyon ng organikong pataba, Nagbibigay din kami Compound na linya ng produksyon ng pataba para sa iyong negosyo sa pataba. Ang linya ng produksiyon ng compound na pataba ay naiiba sa linya ng produksyon ng organikong pataba. Kasabay nito, Mayroon itong iba't ibang proseso ng produksyon.

Para sa paggawa ng compound na pataba, Dapat nating ihanda ang compound fertilizer powder nang maaga. At paglalagay ng mga pulbos na ito sa static na batching machine para sa pagkuha ng compound fertilizer powder na may tamang proporsyon.

- Pagkatapos ang compound fertilizer powder ay maaaring makapasok sa susunod na hakbang-paghahalo. Sa pamamagitan ng dobleng shaft na pahalang na panghalo, Makakakuha ka ng materyal na pataba na naghahalo nang maayos.

- Sa pamamagitan ng paraan, Ang ilan sa mga compound na pataba na hilaw na materyal ay bukol. Dapat mong gamitin ang Cage Crusher upang durugin ang mga compound na materyales na pataba. At ang materyal ay magbabago mula sa bukol hanggang pulbos.

- Susunod ay ang proseso ng butil. Ang hakbang na ito ay ang mahalagang bahagi ng linya ng produksyon ng fertilizer ng tambalan. Para sa pagkuha ng compound na pataba na maganda at madaling iimbak. Dapat mong gamitin ang FPD Rotary Drum Granulator upang makagawa ng mga pellets ng pataba.

- Upang makuha ang nakabalot na pataba ng butil, Dapat mo ring tapusin ang mga proseso ng pagpapatayo, Paglamig, screening at packing.

Matapos ang mga prosesong ito, Maaari kang makakuha ng compound na pataba.

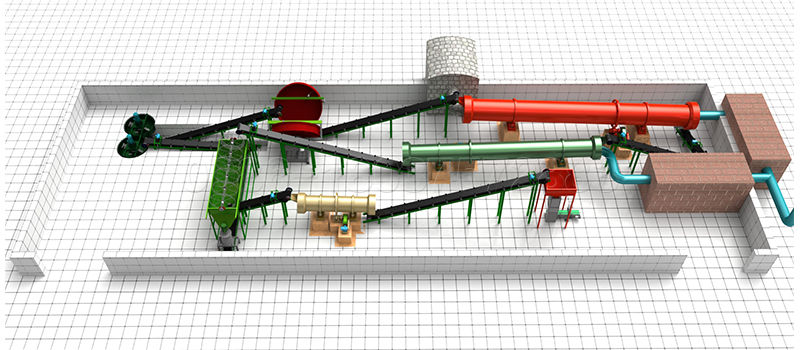

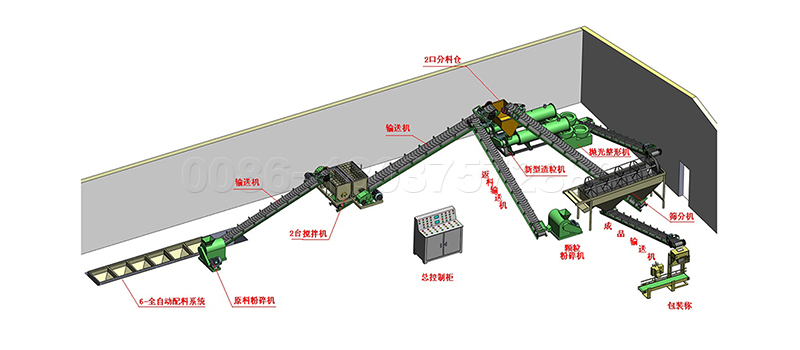

Paano mo mai -disenyo ang iyong halaman ng pataba?

Kung mayroon kang isang halaman ng pataba, Maliban sa kagamitan sa paggawa ng pataba, Ang problemang kailangan mong isipin ay ang layout ng halaman ng pataba. Dahil ang pasilidad ng pataba ay mahalaga, Kailangan mong i -install ang kagamitan sa isang makatuwirang paraan. Sa gayon, Paano mo mai -disenyo ang iyong halaman ng pataba?

- Kung mayroon kang isang malaking sukat na pataba ng pabrika, Hindi mo kailangang mag -alala tungkol sa kung mayroon kang sapat na puwang upang mai -install ang kagamitan sa pataba. Ang kailangan mong isaalang -alang ay kung paano ilagay ang kagamitan sa pataba sa isang tamang paraan. Ang FPD Fertilizer Plant Designer ay makakatulong sa iyo upang malutas ang problemang ito.

- Sa kabilang banda, Kung mayroon kang isang maliit na scale na kumpanya ng pataba, Mas malalaman mo kung paano i -save ang iyong puwang sa paggawa. Sa teknolohiyang mabibigat na industriya ng FPD, Mayroon kaming bucket elevator sa halip na mobile belt conveyor, Makakatulong iyon sa iyo na i -save ang puwang ng produksyon sa lalong madaling panahon.

- Bilang karagdagan, Kung mayroon ka pa ring iba pang mga kinakailangan, Mangyaring makipag -ugnay sa amin, Susubukan namin ang aming makakaya upang malutas ang iyong problema.

Alam mo ba ang pangunahing proseso ng paggawa ng pataba ?

Proseso ng pag -compost

Ang proseso ng pag -compost ay ang bahagi ng linya ng produksiyon ng organikong pataba. At halaman ng pataba ng FPD para sa pagbebenta ng compost make machine para sa iyong paggawa ng pataba . Kung nais mong bumuo ng isang halaman ng pataba o linya ng produksyon ng pataba, Kailangan mong malaman ang proseso ng pag -compost. Dahil maraming mga nakakapinsalang microorganism sa hilaw na materyal. Kung ang organikong pataba ay inilalapat nang direkta sa bukid, Iyon ay makakasama sa iyong mga pananim. Sa panahon ng proseso ng pag -compost, Maaari kang gumamit ng machine ng paggawa ng compost upang makitungo sa organikong materyal. Sa tulong ng paggawa ng machine, Maaari itong i -convert ang hilaw na materyal sa fermented fertilizer, Alin ang malusog para sa iyong mga halaman at pananim. Ano pa, Lubhang pinapabuti nito ang iyong kahusayan sa paggawa ng compost.

Proseso ng Granulate

Pangkalahatang nagsasalita, Ang proseso ng pag -granulate ay ang pinakamahalagang bahagi ng Ang linya ng produksyon ng butil ng pataba. Karaniwan, Pagkatapos ng pagdurog, Ito ay proseso ng butil. Ang layunin ng butil ay upang makabuo ng mga butil ng pataba mula sa pinong pulbos na mga pataba. Kumpara sa pulbos na pataba, Ang butil na pataba ay mas maganda at mas madaling mag -imbak. Upang maging matapat, Kung nais mong makakuha ng butil na pataba, Kailangan mong gumamit ng propesyonal na kagamitan upang matulungan ka.

Sa FPD, Mayroon kaming iba't ibang mga granulator ng pataba upang matulungan ka. Tulad ng, Bagong Uri ng Organic Fertilizer Granulator, Double roller extrusion pellet making machine, Rotary drum churning granulator, disc pellet mill, Rotary churning granulator. Mayroong isang mahalagang bagay na dapat mong malaman, Ang makina na gumagawa ng mga organikong pellets ng pataba ay naiiba sa makina na gumagawa ng tambalang mga pellets ng pataba. Dapat kang gumamit ng bagong uri ng organikong fertilizer granulator, disc granulator o rotary drum churning pellet paggawa ng makina sa Gumawa ng mga pellets ng organikong pataba. Kung nais mong gumawa ng tambalang butil na pataba, Dapat mong gamitin ang dobleng roller extrusion granulator, disc granulator o rotary drum pellet making machine.

Para sa pagbuo ng isang halaman ng pataba, Gaano karaming pera ang kailangan mong gastusin?

Walang alinlangan na ang bawat tagagawa ng produksiyon ng pataba ay nais na malaman ang gastos ng pag -set up ng isang halaman ng pataba. Sa katunayan, Maraming mga kadahilanan na kailangan mong isaalang -alang.

- Ang presyo ng linya ng produksyon ng pataba. Ang isang kumpletong linya ng produksiyon ng pataba ay may kasamang isang buong makina ng paggawa ng pataba. Ang mga makinang paggawa ng pataba na ito ay ang pinakamahalagang bahagi upang makagawa ng pataba. At ang gastos ng iba't ibang mga makinang paggawa ng pataba ng kapasidad ay may iba't ibang presyo, Kailangan mong ibigay ang iyong mga kinakailangan sa iyong tagagawa ng paggawa ng fertilizer machine. Pagkatapos ay bibigyan ka nila ng tumpak na presyo.

- Ang gastos ng site ng paggawa ng pataba. Tulad ng alam nating lahat, Ang presyo ng site ng pataba ay din ang bahagi ng gastos ng halaman ng pataba. Kung nais mong i -save ang iyong gastos sa paggawa ng halaman ng pataba, Maaari mong piliin ang site na malapit sa bansa.

- Ang gastos ng pataba na hilaw na materyal. Para sa pagkuha ng pataba kung ano ang gusto mo, Hindi mo maaaring balewalain ang hilaw na materyal ng pataba, tulad ng hayop na tae, Fertilizer ng Agrikultura. Kailangan mong magbayad ng pera dito. Nangangahulugan ito na dapat kang makahanap ng isang maaasahang pataba na raw material supplier.

Ang makina ng paggawa ng pataba ng FPD ay ibinebenta sa India at Europa.

Saan mo magagamit ang pataba na ginawa ng FPD Fertilizer Making Machine?

Ang organikong pataba na ginawa ng aming kagamitan sa pataba ay makakatulong sa iba't ibang mga halaman na lumago nang mas mahusay. Kaya ang application ng organikong pataba ay napakalawak.

- Maaari naming gamitin ito sa bukid. Ito ang pangunahing aplikasyon na napunta namin. Nabanggit na namin dati, Maraming mga benepisyo kung inilalagay namin ang organikong pataba sa bukid.

- Bilang karagdagan, Maaari rin nating ilagay ito sa Hardin. Halimbawa, ang rosaryo. Ang organikong pataba ay gagawing mas maliwanag ang bulaklak at mas maganda.

- Ang organikong pataba ay maaari ring magamit sa Landscaping ng Lungsod. Ang mga puno at damo ay magiging berde sa pamamagitan ng paglalapat ng organikong pataba.

Bakit pinili ng aming mga customer ang FPD upang gumawa ng kagamitan sa pataba para sa kanilang halaman ng pataba?

After-Sales Service

Sa ibabaw 30 karanasan sa paggawa ng taon, Nagbibigay ang FPD ng lahat ng mga uri ng organikong&Compound Fertilizer Plant na ibinebenta. Kung nais mong hanapin ang kumpanya na may planta ng pataba na ibinebenta. Ang FPD Heavy Industry Technology ay ang iyong pinakamahusay na pagpipilian. Mayroon kaming higit pa sa 100 Mga Serbisyo sa Serbisyo. Sasagutin nila ang anumang katanungan na nakatagpo mo. Bibigyan ka namin ng "15 minuto ng mabilis na pagtugon, 24 Mga oras na nakumpleto ”serbisyo.